What we do

Our end-to-end mining technology solutions tackle our customers' biggest challenges

Extraction

Comminution

Processing

Tailings

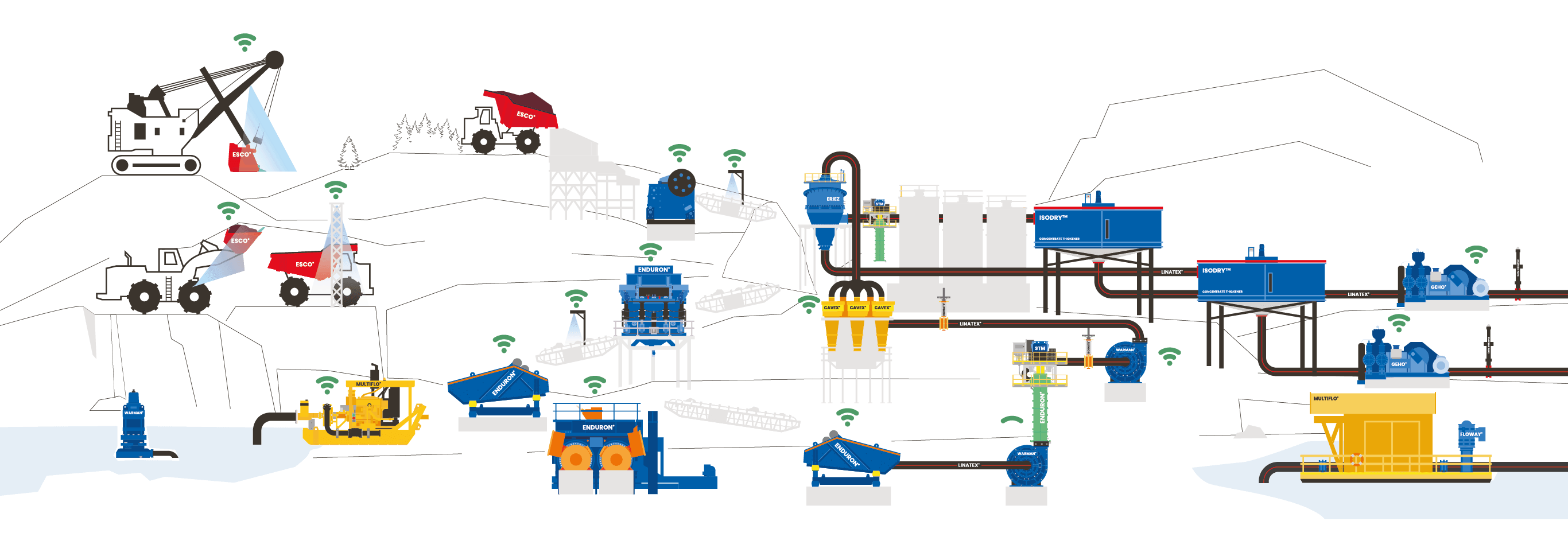

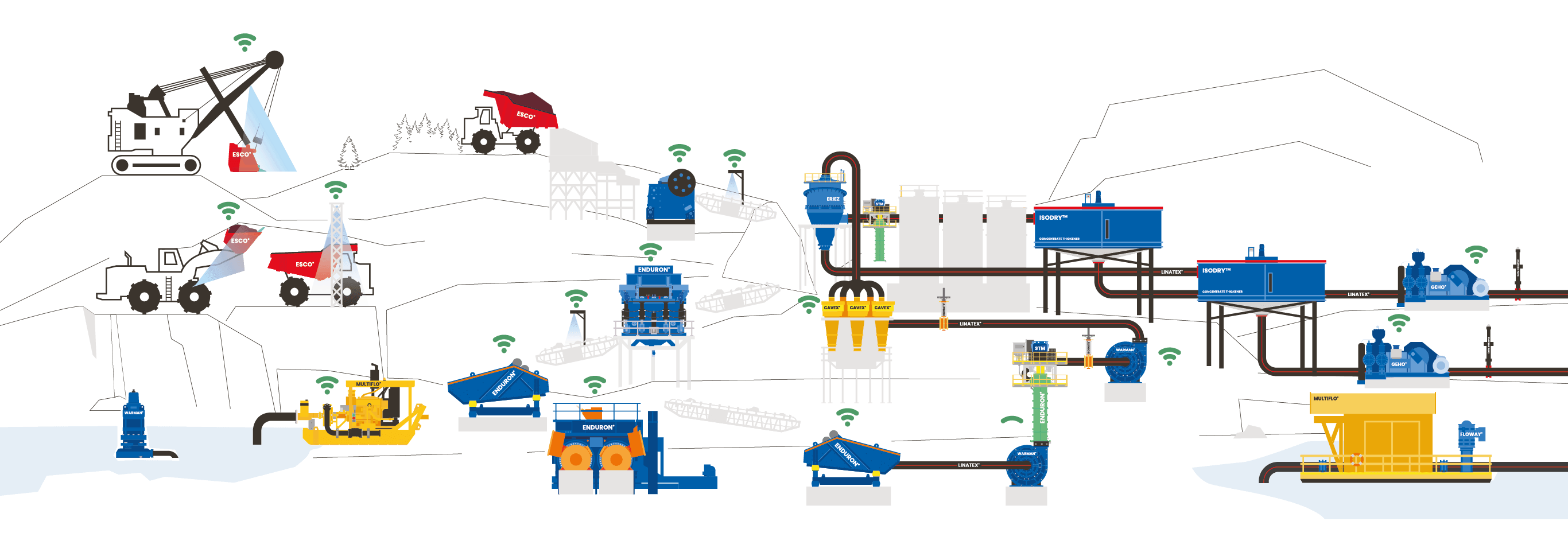

Transformational flowsheets empowered by MOTION METRICS™ and NEXT intelligent solutions

our brand ESCO®

our brand ENDURON®

our brands

WARMAN®, CAVEX®, ENDURON®, LINATEX®

our brand GEHO®

4,900

tonnes CO2e annual saving from loading efficiency1

Move less rock

Miners want to reduce effort spent on processing zero and low grade ore. We help them optimise the material entering their processing plant.

Use less energy

Mining today is very energy intensive. Our solutions deliver significant energy savings and lower CO2 emissions.

Use water wisely

Water is fundamental in minerals processing. Our solutions increase water recovery, recycling and introduce water-free steps.

Create less waste

Today over 90% of waste rock ends up in tailings. We help manage the tailings produced more safely and sustainably.

10%

more efficiency from ore monitoring and sorting

40%

less energy using ENDURON® HPGR technology2

38%

less energy using stirred milling3

43%

less energy using coarse particle flotation4

55%

less water using Terraflowing™ dewatering solutions5

50%

less energy and 30% less water using GEHO® pumps6

01

02

03

04

1 Savings = 3,000 t/y haulage + 1,900 t/y reduced usage of lower priority loaders

Extraction

Extraction

Comminution

Comminution

Processing

Tailings

Tailings

Mining today is very energy intensive. Our solutions deliver significant energy savings and lower CO2 emissions.

Click the icons below to discover how our technology solutions are used across extraction, comminution, processing and tailings.

Weir's transformational flowsheets are accelerating more sustainable mining

up to 4,900 tonnes CO2e annual savings from loading efficiency

up to 40% less energy using ENDURON® HPGR, 38% less energy using stirred milling and 43% less energy using coarse particle flotation

up to 55% less water using Terraflowing™ dewatering solutions, and up to 50% less energy and 30% less water using GEHO® pumps

4 up to 43% compared to a conventional circuit

5 up to 55% less water compared to a thickener alone

6 up to 50% compared to a conventional circuit

Boosted by digital to help miners address the challenges of declining ore grades, maximise production efficiency and reduce CO2e emissions

2 up to 40% compared to a conventional circuit

3 up to 38% compared to a conventional circuit

What we do

Our end-to-end mining technology solutions tackle our customers' biggest challenges

Click the icons below to discover how our technology solutions are used across extraction, comminution, processing and tailings.

04

Create less waste

Today over 90% of waste rock ends up in tailings. We help manage the tailings produced more safely and sustainably.

03

Use water wisely

Water is fundamental in minerals processing. Our solutions increase water recovery, recycling and introduce water-free steps.

Mining today is very energy intensive. Our solutions deliver significant energy savings and lower CO2 emissions.

02

Use less energy

Mining today is very energy intensive. Our solutions deliver significant energy savings and lower CO2 emissions.

01

Move less rock

Miners want to reduce effort spent on processing zero and low grade ore. We help them optimise the material entering their processing plant.

Boosted by digital to help miners address the challenges of declining ore grades, maximise production efficiency and reduce CO2e emissions

Weir's transformational flowsheets are accelerating more sustainable mining

up to 4,900 tonnes CO2e annual savings from loading efficiency

up to 40% less energy using ENDURON® HPGR, 38% less energy using stirred milling and 43% less energy using coarse particle flotation

up to 55% less water using Terraflowing™ dewatering solutions, and up to 50% less energy and 30% less water using GEHO® pumps

Transformational flowsheets empowered by MOTION METRICS™ and NEXT intelligent solutions

Extraction

our brand ESCO®

4,900

tonnes CO2e annual saving from loading efficiency1

1 Savings = 3,000 t/y haulage + 1,900 t/y reduced usage of lower priority loaders

Extraction

10%

Extraction

more efficiency from ore monitoring and sorting

Comminution

our brand ENDURON®

40%

Comminution

less energy using ENDURON® HPGR technology2

2 up to 40% compared to a conventional circuit

38%

Comminution

less energy using stirred milling3

3 up to 38% compared to a conventional circuit

Processing

our brands

WARMAN®, CAVEX®, ENDURON®, LINATEX®

43%

Processing

less energy using coarse particle flotation4

4 up to 43% compared to a conventional circuit

Tailings

our brand GEHO®

55%

Tailings

less water using Terraflowing™ dewatering solutions5

5 up to 55% less water compared to a thickener alone

50%

Tailings

less energy and 30% less water using GEHO® pumps6

6 up to 50% compared to a conventional circuit

What we do

Our end-to-end mining technology solutions tackle our customers' biggest challenges

Click the icons below to discover how our technology solutions are used across extraction, comminution, processing and tailings.

04

Create less waste

Today over 90% of waste rock ends up in tailings. We help manage the tailings produced more safely and sustainably.

03

Use water wisely

Water is fundamental in minerals processing. Our solutions increase water recovery, recycling and introduce water-free steps.

02

Use less energy

Mining today is very energy intensive. Our solutions deliver significant energy savings and lower CO2 emissions.

01

Move less rock

Miners want to reduce effort spent on processing zero and low grade ore. We help them optimise the material entering their processing plant.

Boosted by digital to help miners address the challenges of declining ore grades, maximise production efficiency and reduce CO2e emissions

Weir's transformational flowsheets are accelerating more sustainable mining

up to 55% less water using Terraflowing™ dewatering solutions, and up to 50% less energy and 30% less water using GEHO® pumps

up to 40% less energy using ENDURON® HPGR, 38% less energy using stirred milling and 43% less energy using coarse particle flotation

up to 4,900 tonnes CO2e annual savings from loading efficiency

Transformational flowsheets empowered by MOTION METRICS™ and NEXT intelligent solutions

our brand ESCO®

4,900

tonnes CO2e annual saving from loading efficiency1

1 Savings = 3,000 t/y haulage + 1,900 t/y reduced usage of lower priority loaders

Extraction

10%

Extraction

more efficiency from ore monitoring and sorting

Extraction

our brand ENDURON®

40%

Comminution

less energy using ENDURON® HPGR technology2

2 up to 40% compared to a conventional circuit

38%

Comminution

less energy using stirred milling3

3 up to 38% compared to a conventional circuit

Comminution

our brands

WARMAN®, CAVEX®, ENDURON®, LINATEX®

43%

Processing

less energy using coarse particle flotation4

4 up to 43% compared to a conventional circuit

Processing

our brand GEHO®

55%

Tailings

5 up to 55% less water compared to a thickener alone

less water using Terraflowing™ dewatering solutions5

50%

Tailings

less energy and 30% less water using GEHO® pumps6

6 up to 50% compared to a conventional circuit

Tailings